Performs maintenance duties required in order to maintain production equipment in a manufacturing environment.

Position Responsibilities:

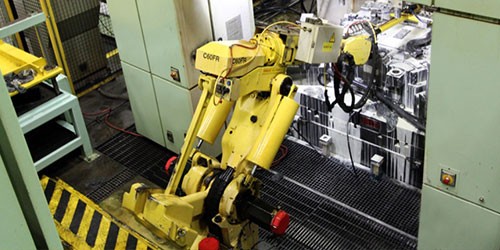

- Perform highly diversified duties to repair and maintain automated production equipment.

- Diagnose problems, replace or repair parts, detect and replace defective parts, test and make adjustments to automated production equipment.

- Perform regular preventive maintenance on machines and equipment.

- Use a variety of hand and power tools..

- Use of programmable logic control systems (PLC’s) to program and troubleshoot automated equipment.

- Perform general clean-up and organization of work area (SCORE- Safety, Cleanliness, Organization, Responsiveness, and Efficiency).

- Other duties as assigned to ensure up-time of automated production equipment, etc.

Qualifications:

- Associate’s degree in Electrical/Mechanical field; or High School diploma/GED with 3+ years of industrial maintenance experience; or High School diploma/GED plus meet the requirements of the Skillstrac Training program as outlined in company policy.

- Follow all safety requirements of the company – PPE, (hat, glasses, steel-toed boots, uniform, hearing protection, gloves, etc.) safe job behaviors, etc.

- Experience in trouble shooting and equipment maintenance of electrical, mechanical, pneumatic, hydraulic and robotics problems on automated equipment.

- Regularly required to lift up to 50 lbs.

- Ablility to read and understand Operation Standards, blue prints, maintenance and equipment manuals, etc.

- PLC programming experience highly desirable.

Work Environment:

- Plant environment.

- Must be able to stand for long periods of time.

- Regularly exposed to dust, grease/oil, odors, noise, smoke, etc.

Contact F & P

F & P America Mfg., Inc

2101 Corporate Drive

Troy, Ohio, U.S.A. 45373

Send resume to:

employment@fandp.com

E.O.E.- M/F/D/V

Employment Listing

Employment Listing